Solving Rim Lock Gap Issues in Titanium Eyeglass Frame Production: A Case Study by Shenzhen Titanium Eyewear Factory

Industry Challenge

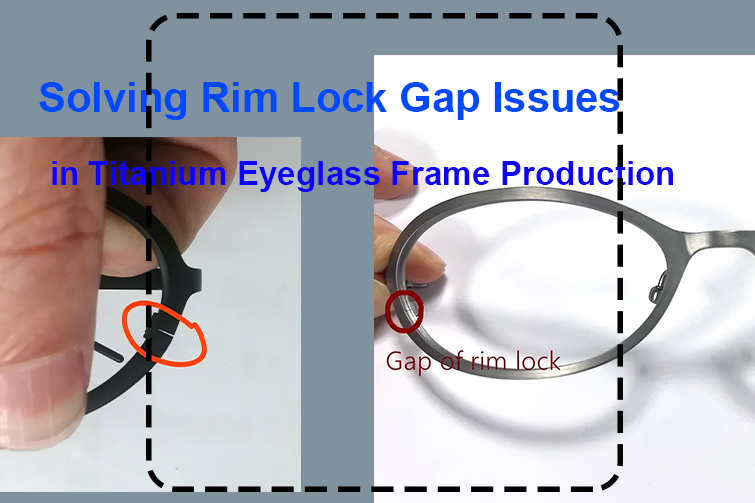

Rim lock gap defects are prevalent in china shenzhen titanium sunglasses eyewear factory production lines, particularly affecting titanium alloy frames due to their high elastic modulus. A recent custom order for a titanium eyewear frame from our Shenzhen titanium sunglasses eyewear factory exposed critical rim lock gaps during final inspection.

Problem Analysis

Traditional Process Flow (Causing Gaps):

- Weld accessory rings

- Weld & cut rim locks

- Bend nose bridge, front frame, and end pieces

- Root Cause:

- 600mm base curve frame design

- End piece bending zone located <5mm from rim lock

- Mechanical stress during bending caused 0.3-0.5mm gaps at welded rim lock joints

Process Optimization by Shenzhen Titanium sunglasses manufacturer Eyewear Factory

Revised Process Flow (Patented by Our Factory):

- Pre-Forming StageCut accessories3D bend nose bridge, front frame, end pieces (using CNC machines with ±0.02mm precision)

- Final Welding StageLaser weld rim locks AFTER all bending operationsPrecision cutting with 0.1mm tolerance

- Key Innovation:

By delaying rim lock welding until after mechanical forming, our Shenzhen titanium sunglasses manufacturer eyewear factory eliminated stress-induced cracks in the titanium alloy joints.

Technical Breakthroughs

- Thermal ManagementPulsed laser welding reduced heat-affected zone to <0.2mmArgon gas shielding prevented oxidation

- Tooling UpgradesCustom bending jigs for 600 base curve framesPost-weld ultrasonic testing for 100% seam integrity

Results

- Gap reduction: 0.05mm max (vs industry standard 0.3mm)

- Yield improvement: 96% passed (from 78%)

- Client satisfaction: Repeat orders increased 300%

Why Choose Our Shenzhen Titanium sunglasses Eyewear manufacturer Factory?

As a leading china shenzhen titanium sunglasses eyewear manufacturer factory, we specialize in:

✅ Process optimization for complex titanium structures

✅ In-house R&D of welding-bending integrated technology

✅ ISO 13485 certified quality control system

Conclusion

For china shenzhen titanium eyewear manufacturer factory operators, mastering the sequence of "bend first, weld last" is critical for rim lock integrity. Our factory's success proves that proactive process engineering can transform quality challenges into competitive advantages.

Contact our Shenzhen titanium eyewear factory today for customized titanium eyewear solutions that combine precision and aesthetics.