Inside the Workshop: How Top Glasses Manufacturers Craft Titanium Frames with Precision

Inside the Workshop: How Top Glasses Manufacturers Craft Titanium Frames with Precision

Titanium eyeglass frames have become a symbol of luxury and durability, blending lightweight comfort with high-tech engineering. For glasses manufacturers, mastering titanium frame production requires a meticulous balance of artistry and advanced technology. In this article, we explore the intricate steps leading brands use to create premium titanium eyewear that meets global standards.

1. Design and Prototyping: The Foundation of Precision

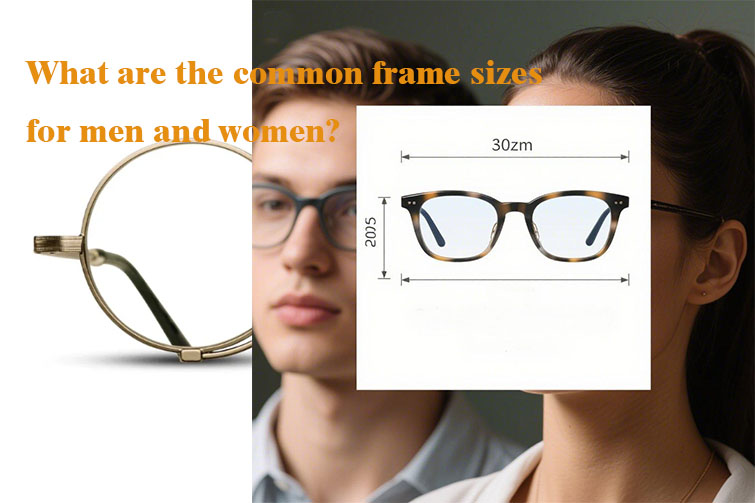

The journey begins with a vision. Leading glasses manufacturers collaborate with clients to design frames that align with brand identity and market trends. Using 3D CAD software, engineers translate sketches into precise digital models, adjusting dimensions for ergonomic fit and cultural preferences. For example, a frame destined for Europe might feature broader temples, while Asian markets favor smaller nose bridges.

Once the design is finalized, prototypes are crafted using rapid prototyping technology. This step ensures every curve and hinge meets exact specifications before mass production.

2. Advanced Manufacturing Techniques

Titanium’s unique properties—strength, corrosion resistance, and hypoallergenicity—demand specialized processing. Here’s how titanium frame production unfolds:

- Mold Fabrication: Custom molds are created to shape titanium sheets into frame components like rims and temples.

- Precision Welding: Techniques like laser welding and rimlock soldering join parts with micron-level accuracy, ensuring structural integrity.

- Surface Refinement: Frames undergo multi-stage polishing to eliminate imperfections, followed by vacuum ion plating (IP plating) for scratch-resistant, vibrant finishes.

- AI-Driven Color Spraying: Robotic systems apply coatings with 99% consistency, reducing human error and waste.

3. Quality Control: Beyond Aesthetics

Top glasses manufacturers integrate rigorous testing at every stage:

- Material Analysis: X-ray fluorescence (XRF) confirms titanium purity (99.6%+ for medical-grade frames).

- Stress Testing: Frames endure 10,000+ bend cycles to simulate long-term use.

- Salt Spray Tests: A 5-year seawater immersion test ensures corrosion resistance, far exceeding industry standards.

4. Innovation in Titanium Frame Production

Leading brands invest in cutting-edge technologies to stay ahead:

- Low-Temperature Hardening: Processing titanium at -196°C increases hardness by 30%, making frames 20% lighter than stainless steel.

- Sustainable Practices: Recycled titanium alloys and water-based plating reduce environmental impact.

- Customization Tools: AR apps allow clients to visualize designs in real-time, streamlining the approval process.

Why Partner with a Reputable Glasses Manufacturer?

Choosing the right partner ensures your brand benefits from:

- Technical Expertise: Access to patented processes and R&D teams.

- Scalability: From small batches to 100,000+ units, with consistent quality.

- Confidentiality: Proprietary designs and client data are safeguarded.

Conclusion

Crafting titanium frames is a blend of science and art. For glasses manufacturers, precision is non-negotiable—from CAD design to final inspection. By leveraging advanced technologies and adhering to strict quality protocols, leading brands deliver eyewear that marries style, comfort, and longevity.

Ready to explore custom titanium frame solutions? Contact our team to discuss how we can bring your vision to life.