In-Depth Analysis of Sunglasses Manufacturing: Process, Quality Control, and Key Points

I. Pre-production Planning and Design

In the realm of Chinese sunglasses manufacturing, the production journey commences with an elaborate design phase. Chinese manufacturers meticulously consider customer preferences, which can vary significantly across diverse domestic and international markets. They also closely track global fashion trends, striving to ensure that their products are not only highly functional but also exquisitely stylish. For example, Chinese designers create conceptual sketches that artfully blend traditional aesthetic elements with modern design concepts. Subsequently, these sketches are transformed into precise technical drawings, where every detail, such as the shape and size of the frame, as well as the connection methods of each component, is meticulously determined. This early-stage planning is of paramount importance as it lays a solid foundation for the entire production process within China's sunglasses industry.

II. Material Selection and Evaluation

Material selection constitutes a pivotal step in Chinese sunglasses manufacturing. Chinese manufacturers have access to a vast array of materials. Metal materials, such as stainless steel and titanium, are highly popular due to their exceptional strength and durability, making them ideal for crafting high-end, long-lasting sunglasses. Acetate fiber, on the other hand, is widely favored for its lightweight nature, comfort, and the extensive range of colors it offers, catering to the diverse fashion demands of consumers. When making material choices, Chinese manufacturers comprehensively evaluate factors such as strength, weight, corrosion resistance, and cost. They source materials both locally and globally to secure the highest quality at a competitive price, thereby enhancing the overall value of their sunglasses.

III. Component Manufacturing and Processing

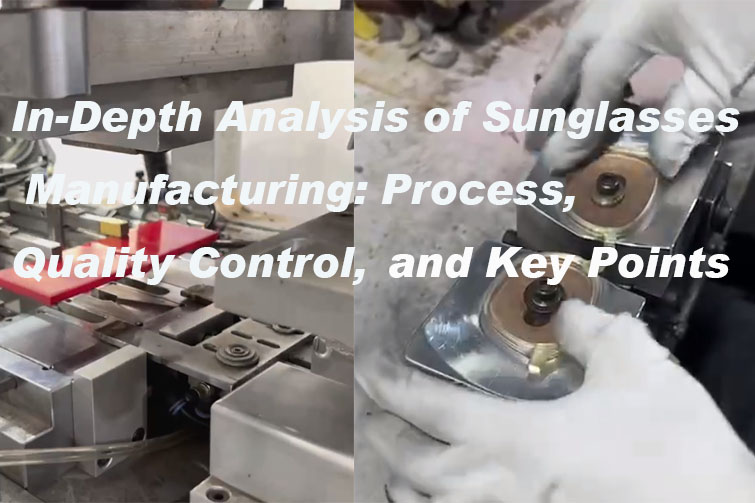

Component manufacturing in Chinese sunglasses production varies according to the material used. For metal components, Chinese factories utilize advanced machinery to process raw materials into frame and temple components through processes like cutting, stamping, and forging. These processes are meticulously controlled to achieve high precision and ensure that the components meet the required specifications. When it comes to acetate fiber components, Chinese manufacturers employ techniques including cutting, heating and shaping, and polishing. The heating and shaping process requires skilled operators to accurately mold the acetate fiber into the desired shape, and the subsequent polishing gives the components a smooth and appealing finish, contributing significantly to the overall quality of the sunglasses.

IV. Assembly and Quality Inspection

In China, once all components are manufactured, they are assembled into complete pairs of sunglasses. Following assembly, a rigorous quality inspection process is carried out. Manufacturers check the stability of the frame to ensure it can withstand normal use without deforming easily. The clarity of the lenses is also a crucial aspect, as it directly impacts the wearer's visual experience. Additionally, they inspect the firmness of the connections between components to prevent any parts from coming loose. This comprehensive inspection ensures that each pair of sunglasses leaving Chinese factories meets strict quality standards, whether destined for the domestic market or for export.

V. Key Points of Quality Control in Chinese Sunglasses Manufacturing

(I) Quality Control of Raw Materials

In Chinese sunglasses manufacturing, quality control begins at the raw material stage. Chinese manufacturers have established strict screening procedures to ensure that only high-quality raw materials are utilized. They conduct thorough inspections of each batch of raw materials, examining physical properties such as hardness and flexibility, as well as chemical composition. This is aimed at preventing unqualified materials from entering the production line, which could potentially lead to defective sunglasses. By maintaining high standards in raw material selection, Chinese manufacturers can guarantee the reliability and durability of their products.

(II) Production Process Monitoring

During the production process in Chinese sunglasses factories, every step is closely supervised. Key control points are set at various stages of manufacturing. For instance, in the component manufacturing process, the temperature and pressure during the heating and shaping of acetate fiber components are carefully regulated. Workers are trained to adhere meticulously to standard operating procedures, which helps maintain the stability of product quality. This real-time monitoring enables Chinese manufacturers to promptly detect and rectify any potential quality issues, reducing waste and ensuring consistent production quality.

(III) Finished Product Quality Testing

Chinese manufacturers conduct a comprehensive inspection of finished sunglasses. This includes a detailed appearance inspection to check for any scratches, blemishes, or color inconsistencies. Dimension measurement is also performed to ensure that the sunglasses fit properly and meet the design specifications. Optical performance testing is a critical part of the process, where factors such as UV protection, lens clarity, and distortion levels are tested. Only sunglasses that pass all these tests are permitted to enter the market, whether it is the bustling domestic market in China or international markets around the world.

If you find any part of the English version needs further improvement, like adjusting the tone or changing specific expressions, feel free to let me know.